How Does a Professional Bus Shelter Factory Ensure High Quality Production

Overview of International Quality Standards Relevant to Bus Shelter Factory Operations

Top manufacturers of bus shelters follow international standards like ISO 9001 for quality management and EN 1090 for structural steel work. These aren't just paperwork exercises they actually set clear rules about tracking materials through production, checking welds properly, and verifying designs before manufacturing starts. When companies comply with these standards, their products can handle real world stresses including at least 150 kg per square meter when snow accumulates on top, plus they need to pass certain fire resistance tests. Bus shelters installed near the coast face extra challenges from salt air and sun damage, so many producers also test their structures according to ASTM G154 guidelines for UV exposure. This prevents rust issues that would shorten the life of shelters in beachside locations where corrosive elements are constantly at work.

Role of ISO and Structural Safety Certifications in Ensuring Compliance

Getting ISO 9001 certified means companies need to document their process controls at every step of production, starting with checking incoming materials right through to those final quality checks on assembled products. Independent auditors come in once a year to make sure everything lines up with safety standards such as EN 1090-1. This particular standard deals with how buildings stand up against strong winds and earthquakes, something critical for structures in high risk areas. For manufacturers exporting into Europe, there's an additional hurdle called CPR 305/2011 that they have to clear. Basically, this regulation makes sure that whatever gets built meets minimum requirements for both safety and how well it actually works over time. Most factories find these compliance processes quite challenging but necessary if they want to stay competitive in today's market.

How Certification Impacts Public Infrastructure Procurement Decisions

Most cities give preference to ISO certified suppliers during their procurement process, something seen in about 8 out of 10 urban tenders according to the Urban Infrastructure Report from 2023. Local governments know this helps cut down on project risks significantly. When manufacturers have these certifications, they show they meet important accessibility requirements like ADA and EN 17210 standards, plus follow specific guidelines for materials that resist damage from vandals. A recent report from the OECD back in 2022 found some interesting numbers too. Certified shelters needed around 37 percent fewer repairs after ten years when compared with those that weren't certified. Makes sense really, since proper certification means better quality control throughout production.

Case Study: Certified Bus Shelter Factory Winning Municipal Contracts

A European factory obtained ISO 9001 and ISO 14001 certifications in 2021, resulting in a 150% increase in municipal contracts by 2023. Their rigorous quality management practices enabled rapid approval for a 400-unit shelter network in Hamburg, Germany, where audit-ready documentation reduced procurement review time by six weeks.

| Standard | Scope | Compliance Benefit |

|---|---|---|

| ISO 9001:2015 | Quality Management Systems | Reduces defects by 21% (2023 Manufacturing Report) |

| EN 1090-2 | Structural Steel Execution Class 2 | Ensures wind resistance up to 130 km/h |

| ASTM E283-04 | Air Infiltration Testing | Validates shelter enclosure weatherproofing |

| ADA 4.3 | Accessibility Guidelines | Mandates 36" clear pathways and braille signage |

Selection of Durable and Sustainable Materials in Bus Shelter Manufacturing

Manufacturers of bus shelters are turning to modern materials science when trying to find that sweet spot between lasting strength and being environmentally friendly. Most go with stainless steel for their frames because it resists rust much better than regular carbon steel actually about three times better according to some tests. And these shelters can last around fifty years in city environments as per the Public Infrastructure Materials Report from 2023. The real benefit shows up along coastlines though. Salt air causes serious problems there, costing roughly seven hundred forty thousand dollars every year just on fixing damaged transit structures like these shelters according to Ponemon's research in 2023.

Polycarbonate glazing solves the problem of keeping things see-through without breaking easily or getting damaged over time. The newer versions stop about 99 percent of harmful UV rays and can handle pretty serious impacts too. Think about it like this: they stand up to the force of a 1 kilogram steel ball falling from two meters high. Even after being tested for 10 years in harsh conditions, these panels only turn yellow by less than half a percent, which means they keep looking good for much longer than most materials would. That kind of durability makes them great for applications where appearance matters but strength is also essential.

Key innovations driving sustainable manufacturing include:

- Modular steel assemblies that reduce on-site welding by 70%

- Recycled aluminum composites meeting virgin material strength benchmarks

- Bio-based polymer cladding with Class A fire ratings

While urban contracts increasingly require 30—50% recycled content, technical limitations remain. Virgin stainless steel still outperforms recycled alternatives in load-bearing applications, showing a 92% lower failure rate in 15-year fatigue tests. However, advances in post-industrial reprocessing now support modular designs with 40% faster installation times without compromising structural integrity.

Precision Manufacturing and Smart Production Techniques

Precision Cutting and Welding Techniques Used in a Professional Bus Shelter Factory

Facilities today rely on laser cutting systems that can achieve around 0.1 mm accuracy when working with stainless steel parts. This level of precision helps create tight fits needed for joints that keep out water and moisture. For welding operations, robotic arms now come with smart seam tracking tech that keeps the weld penetration consistent even over long distances. Think about those big 20 meter roof panels they have to weld together. These machines actually cut down on thermal distortion problems by about one third compared to what happens with manual welding techniques according to a study from Manufacturing Solutions Journal last year.

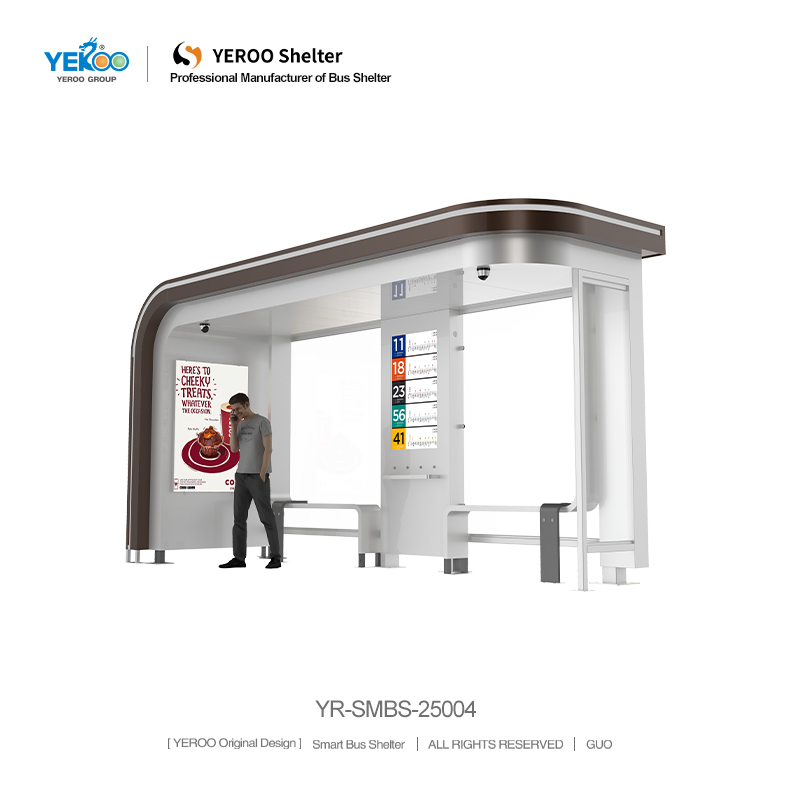

Automated Assembly Lines Versus Custom Fabrication for Urban Transit Projects

- Automated systems produce up to 120 standardized shelters per week with 99.8% component interchangeability

- Custom fabrication supports specialized designs, including curved glass canopies and heritage-style units, within 45-day lead times

- Hybrid models combine 75% automated modular subassemblies with site-specific finishing

Corrosion-Resistant Coatings and Their Long-Term Performance in Coastal Cities

Multi-stage coatings featuring zinc-rich primers and fluoropolymer topcoats deliver proven protection:

| Exposure Duration | Salt Spray Resistance | Real-World Performance |

|---|---|---|

| 5 years | 2,000 hours | 98% coating integrity |

| 10 years | 4,500 hours | 89% coating integrity |

Integration of Smart Manufacturing (IoT) in Bus Shelter Production Workflows

Sensor-equipped jigs monitor 217 quality parameters during assembly, feeding real-time data to AI-driven predictive maintenance platforms. This IoT integration reduces material waste by 22% and accelerates municipal inspection approvals by 40% compared to traditional workflows.

Rigorous Testing and Compliance with Safety Regulations

Structural load testing for wind and snow resistance in extreme climates

Shelters undergo structural testing beyond international benchmarks, simulating wind speeds over 150 mph and snow loads up to 75 psf. These protocols align with ISO 6507:2023 requirements for public infrastructure, ensuring reliability in hurricane-prone coastal zones and high-altitude regions.

Fire safety ratings and flammability tests for interior components

All combustible materials are tested under ASTM E84 for Class A flame spread, limiting smoke development to below 450 and flame propagation to no more than 6 feet. Fire-retardant adhesives and low-VOC foams minimize toxicity risks during combustion, making them suitable for enclosed or underground transit environments.

Impact resistance evaluations using simulated vandalism and weathering tests

Panels endure over 50,000 impact cycles via pendulum testers simulating blunt-force attacks, alongside 2,000-hour salt spray exposures replicating coastal conditions. UV-stabilized polycarbonate retains 92% light transmission after 15 years of accelerated weathering, maintaining clarity and strength across extreme temperatures (-40°F to 120°F).

Compliance with ADA and accessibility regulations in shelter design

Designs incorporate 36-inch clear pathways, braille-enabled fare machines, and auditory alerts at 65 dB to meet ADA Title II standards. Recent updates require contrast ratios of at least 70% between signage and backgrounds, improving visibility for low-vision users during nighttime operations.

Final Inspection, Finishing, and Field Installation Quality Control

Multi-stage quality checkpoints before shipment from the bus shelter factory

Certified factories enforce 7–10 inspection stages to ensure structural and safety compliance. First Article Inspection (FAI) verifies prototype accuracy, while In-Process Quality Control (IPQC) monitors weld integrity and dimensional tolerances. Final inspections employ coordinate measuring machines to confirm alignment within 0.5 mm precision (2024 Manufacturing Quality Report).

Surface finishing: Powder coating, polishing, and anti-graffiti treatments

High-traffic shelters receive a three-stage surface treatment: alkaline washing for rust prevention, electrostatic powder coating for UV resistance, and nano-coatings that reduce graffiti adhesion by 67% (Urban Materials Study 2023). Coastal installations include zinc-rich primers, extending service life by 12–15 years in salt-laden environments.

Documentation and traceability of components for municipal audits

Each production batch features QR-coded labels tracking material origins, welding parameters, and inspector sign-offs. These digital records, secured through blockchain technology, allow cities to validate compliance with ISO 9001:2015 and local procurement rules.

Pre-assembly validation and site-specific customization protocols

Factories perform full-scale mockups using 3D site scans to verify installation clearances and ADA compliance. Modular designs enable adjustments for underground utilities or heritage district aesthetics without disrupting production timelines.

Collaboration between bus shelter factory engineers and city planners

Joint engineering teams address challenges such as wind tunnel effects or emergency access during prototyping, reducing post-installation modifications by 82% (Transit Infrastructure Journal 2024).

Long-term maintenance support and warranty programs as quality indicators

Top manufacturers offer 15-year warranties covering structural defects and finish degradation, supported by IoT-enabled monitoring systems that proactively alert municipalities to emerging issues before failures occur.