Why Are Modular Bus Shelters a Flexible Solution for Modern Transit

Phenomenon: Increasing Demand for Scalable Transit Infrastructure

The United Nations predicts that around 68% of people worldwide will live in cities by 2023, which puts regular transportation networks under serious strain. Smaller to medium sized towns face particular challenges here since passenger numbers often swing wildly - sometimes changing by as much as 40% depending on tourist seasons or when businesses relocate their operations. Against this backdrop, flexible bus stop designs are becoming increasingly important solutions. These modular structures offer something traditional ones don't: they can grow or shrink according to need while still being reused multiple times. A recent study from the Urban Mobility Institute found that about two thirds of public transport organizations struggle with money issues when trying to construct long term facilities. That makes these adaptable options not just smart but almost necessary for many communities facing tight budgets.

Principle: How Modular Design Meets Rapid Urbanization Needs

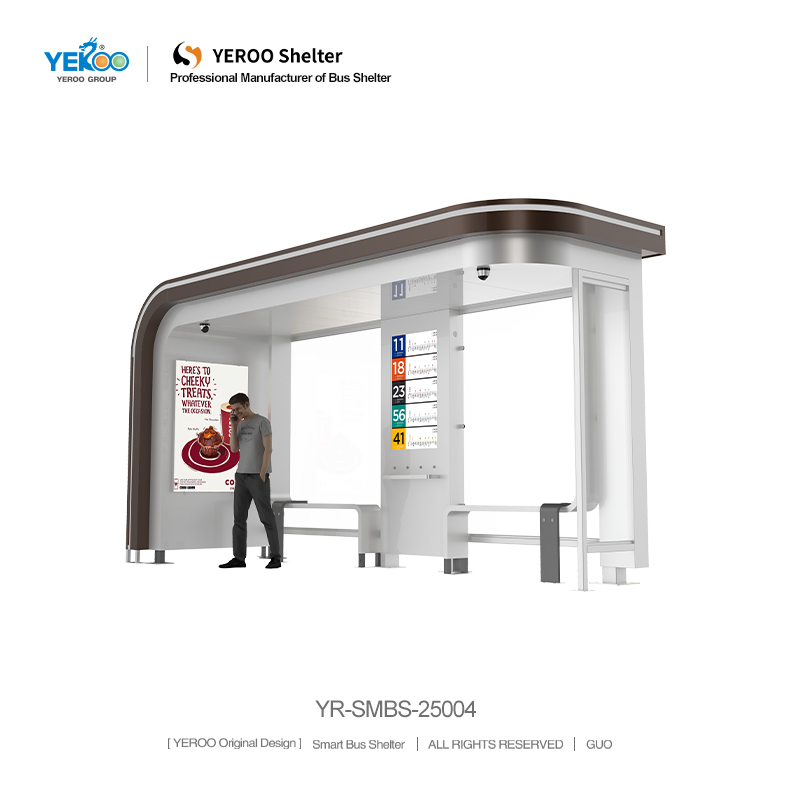

These modular shelters go up in just under two weeks while traditional concrete buildings take anywhere from six to eight months to complete. The prefabricated nature means they come with parts that can actually adapt to different situations. Think adjustable roofs and walls with built-in ventilation so places can customize them based on local weather conditions. Need bigger overhangs where it rains a lot? Got it. Want better air flow in hotter areas? That works too. According to research published last year, this kind of design cuts down on maintenance expenses over time by around 32%, mainly because replacement parts are all standard sizes. Plus, since everything fits together like puzzle pieces, municipalities don't have to commit to full scale deployment right away. They can start small, test things out on busy transit routes first before expanding elsewhere.

Case Study: Deployment in Mid-Sized Cities with High Route Volatility

The city of Riverside saw a pretty significant jump in bus reroutes last year, with 27% more instances where flooding forced changes to regular routes. Something had to be done, so officials went ahead and put up 85 new modular bus shelters across town. These weren't your average shelters either they came equipped with floors raised above ground level and solar panels that could actually be removed when needed. The whole project saved taxpayers around half a million dollars compared to what it would have cost otherwise, plus all those shelters stayed operational even during the worst storms we saw back in 2023. And then there was the time when three entire bus lines got moved for good. Thanks to adjustable seating arrangements and flexible signage systems, everything was back up and running properly within just three days something that would normally take about six weeks if they used conventional construction methods instead.

Accelerating Installation Through Prefabrication and Plug-and-Play Systems

Modular bus shelters achieve rapid deployment by combining factory-built components with standardized interfaces. Off-site fabrication reduces on-site labor by 58–62% (2024 Prefab Architecture Report), as structural frames, cladding, and electrical systems arrive pre-assembled.

How Off-Site Construction Reduces On-Site Labor by Up to 60%

Factory production enables parallel workflows: while site foundations are poured, shelters are constructed off-site under controlled conditions. A 2023 study of urban transit projects showed this method cuts weather-related delays by 41% and reduces equipment transport costs by $18 per linear foot.

Time-to-Deployment Comparison: Traditional vs. Modular Bus Shelter

| Parameter | Traditional Construction | Modular System |

|---|---|---|

| On-site labor hours | 120–150 | 45–60 |

| Installation window | 3–4 weeks | 5–7 days |

| Project duration | 12–18 months | 6–9 months |

Trend: Integration of Smart Components During Prefabrication

Manufacturers now embed IoT sensors, LED lighting controls, and USB charging ports directly during factory assembly. This eliminates post-installation retrofits, which historically added 23% to commissioning costs.

Strategy: Phased Rollouts Enabled by Plug-and-Play Frameworks

Cities like Stuttgart and Brisbane use standardized mounting plates to scale shelter networks alongside transit growth. A 2025 case study demonstrated how this approach reduced corridor upgrade timelines from 14 months to just 26 weeks, streamlining service expansion.

Sustainable Materials and Environmental Performance of Modular Bus Shelters

Modern modular shelters use 65% recycled aluminum in structural frames—a material with a 92% reuse potential, far exceeding concrete’s 43% recovery rate (Ponemon 2023). UV-stabilized polycarbonate panels offer a 12-year lifespan in accelerated weathering tests, delivering durability and natural light transmission without relying on virgin plastics.

Lifecycle Analysis: Lower Carbon Footprint Than Concrete Alternatives

A 2024 transit infrastructure study revealed modular aluminum shelters generate 18.7 metric tons of CO₂ equivalent over 15 years—34% less than comparable concrete installations. This advantage stems from precise factory fabrication, which reduces onsite waste by 61% during deployment.

Controversy Analysis: Bioplastics vs. Durability in High-Traffic Zones

While PLA bioplastics reduce fossil fuel use by 83%, they exhibit 22% lower abrasion resistance than petroleum-based composites under simulated pedestrian traffic. To balance sustainability and longevity, leading engineers now combine bioplastic cladding with steel reinforcement ribs, meeting 15-year warranty standards without compromising eco-goals.

Designing for Extreme Heat: Reflective Coatings and Passive Cooling

Ceramic-coated roof panels reflect 89% of solar irradiance while transmitting 76% of visible light—critical for visibility and thermal comfort. Integrated cross-ventilation channels in modular sidewalls reduce interior temperatures by 6.2ºC without mechanical cooling, aligning with climate-resilient urban design priorities.

Enhancing Climate Resilience in Urban Transit Infrastructure

As climate volatility increases, modular bus shelters are proving essential for maintaining reliable transit services. Their engineered adaptability addresses three core resilience challenges facing modern cities.

Flood-Adaptive Foundations and Elevated Panel Systems

Next-generation shelters feature retractable flooring and marine-grade aluminum substructures rated for 72-hour saltwater immersion. A 2024 analysis of coastal transit infrastructure showed cities using elevated modular platforms reduced flood-related shelter replacements by 63% compared to fixed concrete stops.

Case Study: Hurricane-Prone Coastal Cities Adopting Storm-Resilient Modules

Six Gulf Coast municipalities replaced traditional shelters with modular units equipped with breakaway solar panels and helical pile foundations ahead of the 2023 hurricane season. Post-storm assessments revealed 83% of modular shelters remained functional, compared to just 22% of conventional ones—enabling faster restoration of public transit after Category 4 landfalls.

Trend: AI-Driven Climate Modeling for Site-Specific Shelter Configurations

Agencies are increasingly pairing AI-powered risk modeling with modular manufacturing to tailor shelters to local threats. This allows cities to deploy hurricane-rated units in Miami and heat-deflecting variants in Phoenix from the same product line, optimizing performance while maintaining supply chain efficiency.

Advancing Transit Equity Through Strategic Modular Bus Shelter Networks

Bridging the Gap: Deploying Shelters in Underserved Neighborhoods

Modular shelters enable rapid installation in transit deserts, particularly along routes connecting schools, clinics, and job centers—vital for 63% of low-income commuters (ScienceDirect 2023). A 2023 urban mobility study found strategic placement reduces average walk times to covered stops by 8 minutes in underserved areas.

Data Insight: 78% of Low-Income Riders Lack Adequate Waiting Shade

Weather exposure remains a persistent equity issue: 78% of riders earning under $35,000 annually report insufficient protection from sun and rain. Despite public transit accounting for 71% of trips in these neighborhoods, shelter coverage lags. Modular designs help close this gap with standardized canopies and optional heated seating in colder climates.

Strategy: Mobile Modular Units for Temporary Service Expansion

Cities like Minneapolis deploy trailer-mounted shelters during peak seasons, achieving 90% faster setup than permanent builds. These mobile units serve dual roles—providing immediate coverage and collecting ridership data to inform future fixed installations. Trial deployments during major events reduced stop overcrowding by 40%.

Industry Paradox: Aesthetic Uniformity vs. Community Identity in Shelter Design

Using standard parts instead of custom builds cuts costs around 25%, yet new approaches let buildings express local character while still being efficient. Some designs feature replaceable walls that showcase art from nearby communities, while others have roof shapes inspired by traditional architecture in different regions. Take a recent test program in one of those cities along the mid Atlantic coast - people there were way more supportive of shelters that matched what they saw in their own neighborhoods, with colors and patterns similar to surrounding buildings. The approval rate jumped nearly 40 percent compared to generic structures.