How Does a Modular Steel Bus Shelter Offer Flexibility for Urban Planning

What Makes a Modular Steel Bus Shelter Inherently Adaptable?

Standardized Components Enable Rapid, Scalable Deployment

Modular steel bus shelters are changing how cities deploy these structures because they come in standard pieces that just need putting together on site. Steel frames, panels, and roof sections all show up pre-made so there's no waiting around for custom fabrication. The consistency cuts down installation time quite a bit actually, somewhere between 30 to maybe even 50 percent faster than building each shelter from scratch. City transit departments love being able to roll out shelters gradually too. They might start with ten units along busy routes first, then expand to hundreds more throughout the suburbs without needing different components for each location. When something gets damaged, fixing it becomes much easier since those bolt-on designs mean broken panels can usually be replaced within a few hours rather than taking days to fix. According to some research published last year about city infrastructure, these modular approaches tend to save around 17% in maintenance expenses when compared to traditional shelters over time.

Plug-and-Play Integration with Smart Transit Infrastructure

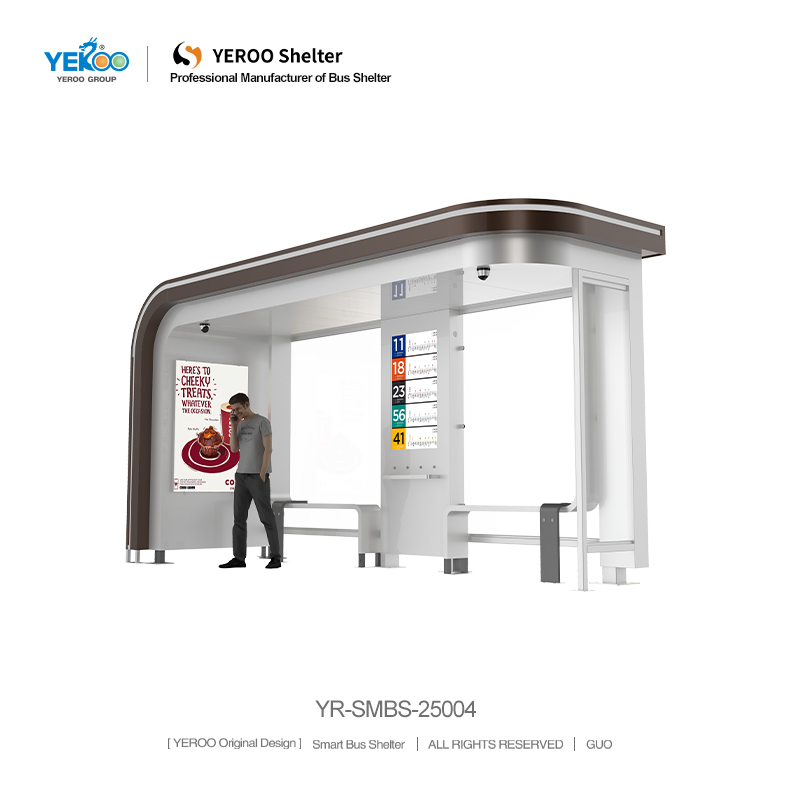

Bus stops today need more than just seating they want to stay connected too, and steel shelters handle this pretty well actually. The columns themselves have hidden channels inside where all the wires run for those fancy digital screens, security cameras, even free internet access at some stops. No need to tear things apart later on. Cities also install standard brackets so they can slap on solar panels or weather monitoring devices whenever money becomes available. Design-wise these shelters aren't one size fits all either. In areas that get constant rain, the roof overhang grows bigger by around 35%, while certain bench areas come with built-in heat elements underneath because nobody wants cold seats after work. Thinking ahead like this saves loads of cash down the road when transportation requirements change. A study done last year found that putting tech in from day one instead of adding it later reduces maintenance costs by roughly 40% over time.

Tailoring the Modular Steel Bus Shelter to Diverse Urban Contexts

Data-Informed Customization: Sizing and Layout Based on Ridership Analytics

Transit planners look at rider numbers all the time when designing those modular steel bus shelters we see everywhere. They check out how many people get on during rush hour, how often buses run along certain routes, and how long folks tend to wait at stops before their ride arrives. All this info helps decide just how big the canopy should be, where benches go, and what kind of standing room makes sense. In busy spots like downtown areas or near train stations, they build bigger shelters that can handle over twenty waiting passengers at once while keeping wheelchair access wide enough for everyone. Meanwhile, smaller towns or less crowded neighborhoods get these compact versions with vertical seats stacked neatly against walls instead of taking up floor space. The whole point is making sure tax money goes toward building something that actually works for real people rather than ending up too small or sitting empty most days. Cities now install these smart sensors right at the boarding area so they can tweak things even after construction finishes based on actual usage patterns throughout different seasons.

Long-Term Value of Steel Construction in Urban Infrastructure Planning

Lifecycle Economics: Higher Upfront Cost vs. 40-Year Resilience and Low Maintenance

Steel bus shelters usually come with a price tag about 20 to 30 percent higher than wooden or concrete options at first glance. But what makes them worth considering is their lasting power and practically no maintenance needed over time. According to various industry reports, these steel structures can last well beyond 40 years in service, while cutting down on yearly maintenance bills somewhere around half. What really stands out about steel is how it handles rust, flames, and harsh weather conditions without breaking down, which means fewer repair jobs down the road. City officials looking after public transportation budgets find this particularly appealing since it lowers overall spending across the lifespan of the shelter. The money saved can then go toward other improvements in neighborhoods, making steel a smart choice economically when designing sustainable transit solutions.

Future-Proofing Cities: Upgradability and Phased Implementation

Modern cities can really benefit when their infrastructure has built-in upgrade potential, and look no further than those modular steel bus shelters as proof. These shelters were made right from the start to handle improvements at the component level. Want to add digital screens showing arrival times? Need emergency alerts during bad weather? How about better USB ports for charging phones? All possible without tearing down the whole shelter structure. This saves a ton of money compared to replacing entire shelters and avoids all that construction headache for local communities. Plus, the modular design lets transit agencies roll out shelters one neighborhood at a time. They can match deployments with available budgets or areas where passenger numbers are growing. Makes sense really. Most city planners agree that taking small steps forward is smarter than waiting for perfect conditions. And since steel lasts so long, every round of upgrades keeps working reliably for years. The result? A public transport system that grows and changes just like the city itself.

FAQ

Why are modular steel bus shelters faster to install compared to traditional ones?

Modular steel bus shelters come in pre-made, standardized components which allow for quicker assembly and installation on-site, cutting down installation time by 30% to 50% compared to building each shelter from scratch.

How do modular steel shelters integrate with smart transit technologies?

The shelters have built-in channels for wiring, allowing easy installation of digital screens, security cameras, and other smart technologies without major modifications.

Are modular steel bus shelters environmentally adaptable?

Yes, they can be customized with climate-responsive features like solar-reflective roofs in deserts or wind-deflecting panels in coastal areas, enhancing sustainability.

What are the economic benefits of choosing steel over other materials?

Though initially more expensive, steel shelters have a longer lifespan (over 40 years) and lower maintenance costs, making them cost-effective over time.

Can steel bus shelters accommodate future technological upgrades?

Yes, steel bus shelters are designed to be easily upgradable at the component level, allowing future technological integrations without major overhauls.