How Does an Easy Assemble Bus Shelter Save Time for Cities

Urban Growth and Rising Demand for Quick Installation of Easy Assemble Bus Shelters

The United Nations predicts that around two thirds of people worldwide will live in cities by mid century. This rapid urban growth puts extra strain on public transport systems everywhere. Standard bus shelters take anywhere from eight to twelve weeks to install, which simply isn't fast enough to meet growing demand. That's where these new quick build shelters come in handy. They're made in factories first then assembled on site within just ten days flat. No need for expensive concrete work or hiring special tradespeople either. Cities can get functional, dry waiting spots up and running at least five times quicker compared to old fashioned methods. Makes sense when we think about how many commuters end up getting soaked waiting for buses during rainstorms.

Challenges of Traditional Construction Methods in Public Transit Infrastructure

Old methods typically take about 40% more man hours according to research from the Urban Transit Institute back in 2023. Plus they run into all sorts of problems with bad weather holding things up and getting stuck waiting on permits. Looking at data from twelve different American cities last year showed something interesting too. The traditional shelter projects ended up costing around $74,500 extra each time compared to those modular options. Why? Because when stuff gets made off site first, most of the actual building work happens inside factories where conditions are stable. About 85% of what needs assembling is done there already, which cuts down on so many variables that can go wrong out in the field.

How Fast Deployment Supports Sustainable, Equitable Public Transportation Goals

Accelerated rollout of easy assemble shelters aligns with climate targets, cutting embodied carbon by 32% through optimized material use (Sustainable Infrastructure Coalition 2023). Cities like Tempe, Arizona, achieved 95% shelter coverage in underserved corridors within 18 months using prefabricated models, increasing off-peak ridership by 22% among vulnerable populations.

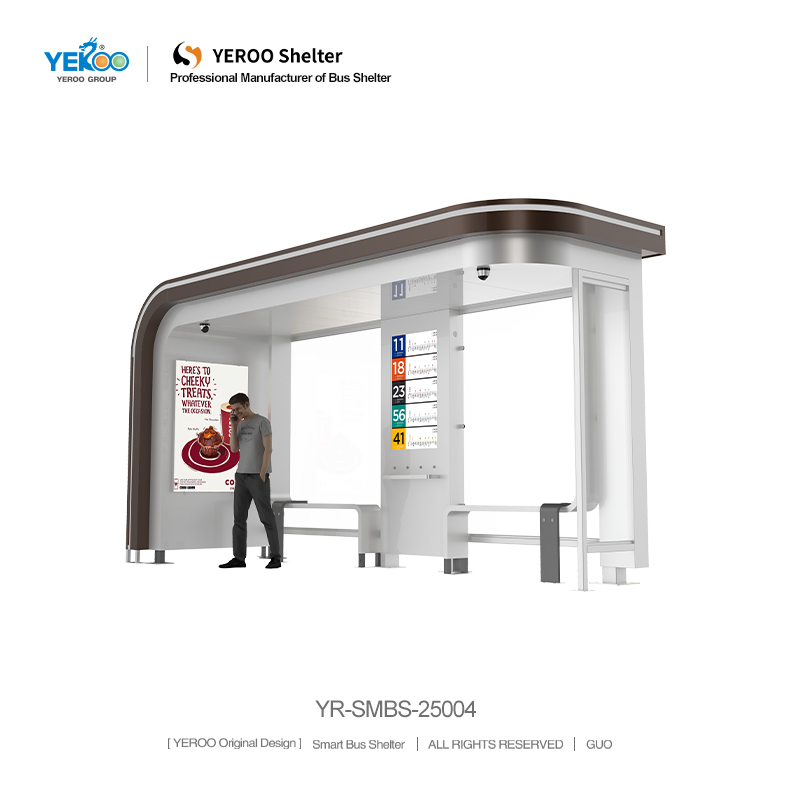

Understanding Modular + Prefabricated Systems in Easy Assemble Bus Shelter Construction

Modular bus shelters are built from factory made parts connected using standard fittings, which makes them much quicker to install compared to old methods. Traditional concrete shelters take weeks to build on site, but these new modular designs come as ready made kits containing everything needed for assembly including pre-made roofs, walls, and all the necessary hardware. Top manufacturers now use computer controlled machines and digital templates to get manufacturing accuracy down to just half a millimeter according to industry research from Ponemon in 2023. The precision ensures everything fits together smoothly when putting the shelter together at the actual location. What's even better is that this method cuts down construction waste by around two thirds without compromising strength since each unit undergoes thorough testing against wind forces and heavy loads before being shipped out.

Impact of Well-Designed Easy Assemble Bus Shelters on Rider Comfort and Satisfaction

New style bus shelters that are quick to put together really improve how people wait for buses. They come with covers that hold up against rain and sun, seats designed for comfort, plus special features such as textured paths for visually impaired passengers. According to research done last year looking at fifteen different transportation setups across cities, riders reported feeling much happier about their waiting experience when these upgraded shelters were available instead of just plain concrete boxes. The difference was pretty significant too about three out of four people said they preferred the nicer shelters. Putting these shelters where most needed makes sure everyone gets fair access, especially those who need extra help moving around. This kind of thoughtful design helps make taking public transport feel respectful rather than something second best.

Reducing Perceived Wait Times and Increasing Usage in Newly Served Areas

Putting real time arrival screens alongside solar powered lights can cut down how long people think they're waiting by around 40 percent according to National Transit Institute research from 2022. Take Los Angeles for example when they installed 150 prefabricated shelters along areas that needed them most. Within just six months, weekday ridership went up nearly 19%. And guess what? Out of all those folks who were asked, 92% said their trips felt more reliable now. Getting these shelters up quickly fills holes in existing transit systems. This makes sense because when new stations appear fast, it draws in people who never rode before since they don't have to wait so long anymore.

Scalable, Customizable, and Durable: Designing Easy Assemble Shelters for the Long Term

Flexible Configurations to Match Diverse Urban Environments and Aesthetic Needs

Bus shelters that are easy to put together work well in different city settings because they come with panels that swap out and frames that fit together like building blocks. Cities don't need special manufacturing when they want to change things up for old neighborhoods, busy transportation centers, or regular bus stops. They just pick what works best for each spot. Take busy train stations for instance, these places often need bigger roofs to protect riders from rain or snow. On the flip side, quieter residential areas usually look better with smaller designs that have plants built right in. What makes this system great is how it keeps everything looking consistent across town while still letting cities install new shelters quickly when needed.

Designing for Accessibility, Climate Resilience, and Long-Term Durability

Today's modern shelters are built to meet accessibility requirements for everyone, featuring things like 36 inch wide ramps and those little raised dots people can feel with their feet. They also use special materials depending on where they're installed. The frames are made from powder coated aluminum, which doesn't rust easily, while the panels are polycarbonate laminates that can handle extreme weather conditions. These components work together to survive temperatures ranging all the way from minus 40 degrees Fahrenheit up to 120 degrees without cracking or warping. Plus they stand up well against salt spray from roads during winter months or moisture in coastal areas. According to research published last year looking at durable transit structures, shelters constructed with these kinds of materials needed about 37 percent fewer repairs after ten years than older models made primarily of steel and glass. That means lower long term costs for cities maintaining public transportation facilities across different climates.

Balancing Speed of Installation with Quality and Maintenance Efficiency

Putting together prefabricated shelters becomes much easier thanks to numbered components and connector systems that don't require tools, which cuts down mistakes at construction sites by almost 90% according to the Modular Construction Report from 2023. The companies making these structures focus on durability too, using robots for welding jobs and special sound wave tests to check for leaks while they're still being built, so these buildings can last well over two decades. After installation is complete, special coatings that resist sun damage combined with hardware that won't corrode mean owners don't have to repaint as often either, stretching maintenance intervals from three years out to eight years. This translates into real money saved over time, cutting yearly expenses by around eighteen dollars for each square foot of shelter space.