What Makes a Metal Bus Shelter Durable for Public Transport Systems?

The Selective Use of Metals Other Than Plastic or Wood

With Yeroo Group, the most dependable metal bus shelters are made of galvanized steel or aluminum alloys. Bus shelters made of aluminum alloys are lightweight and possess attribute such as the absence of rust and corrosion, the ability to withstand snow, rain, wet, and humid air. These alloys can sustain the wind and can withstand the impact of small vehicles. These types of shelters do not rot or deteriorate, and can sustain integrity for decades; posing the best choice for public transport systems.

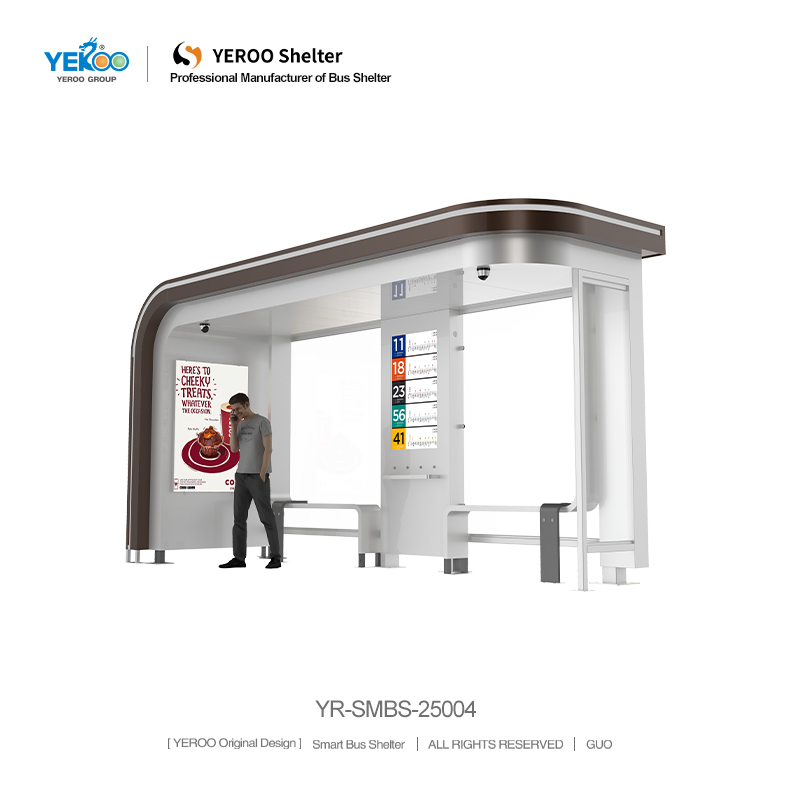

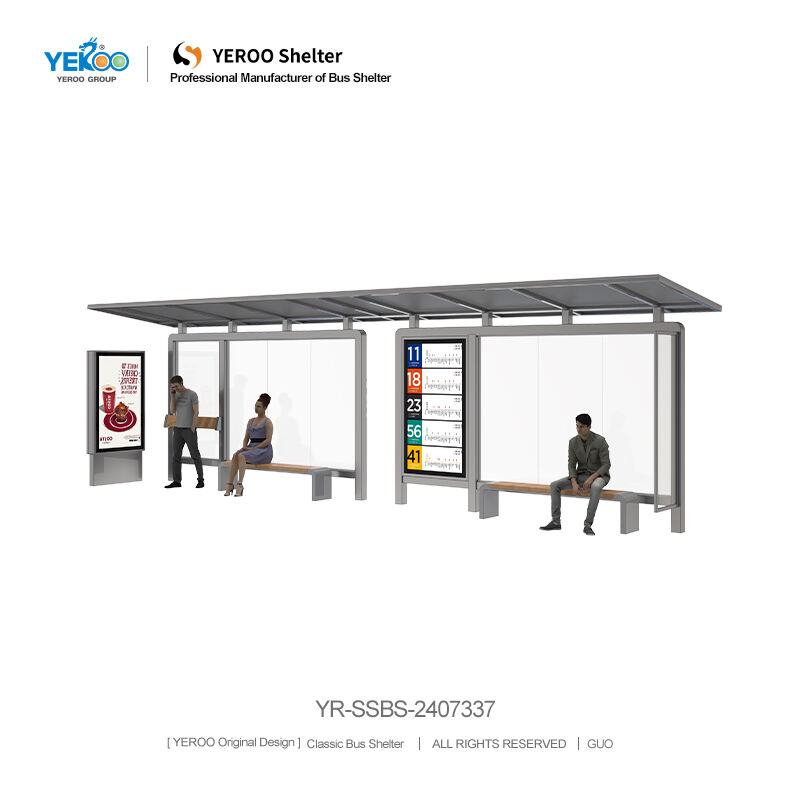

The Rational Structural Design of a Metal Bus Shelter

Yeroo Group bus shelters are made of galvanized steel. These steel variants are coated with zinc, resist corrosion, and can withstand snow, the rain, and humid environments. Metal shelters are also known to not deteriorate. Construction is rational.

Every bus shelter made from metal possesses some basic elements of construction, which includes the metal poles and roofing panels. When poles and panels are attached they are done so with metal bolts or welding, thereby the frame and panels are welded, and bolts are used to connect the roofing panels. If done properly the metal bus shelter is able to withhold the entire weight of the bus. In addition, some poles may be obsequently thicker than some, which means that they are able to withstand more weight and that there is an even distribution of the weight across the bus shelter. Most bus shelters also have oblique roofs which makes every metal bus shelter an even greater construction, while also making there an easier way for the snow and rain to slide off, while preserving the shelter from water damage. Furthermore, even with the addition of these oblique roofs the base of every bus shelter is still cemented and bored deep into the ground, which allows for the shelter to be more secure and stable even when there is extreme weather. These elements combined enhances the metal bus shelter so that it is able to last through sunlight and storm, as well as the snow, showing the durability that the bus shelter possesses.

Other than that the durability of the metal construction requires special treatment, which means the shelter has to be designed with anti-corrosion and weather resistant materials. Most of these bus shelters undergo a coat of color either in a single or triple serum, which increases their protective weather treatment.

The powder coating technique creates a thick and uniform layer on the surface of the metal which protects the surface from scratches, UV rays, and chemical substances such as road salts. The coating also isolates the metal from moisture and air pollutants, thus preventing rusting and fading. Additional anti corrosion surface treatments, such as chrome and anti-rust paints, are often added to metal bus shelters in coastal areas to resist corrosion to salt spray. These additional anti corrosion treatments make sure the bus shelters sustain their quality and do not corrode through their metal structure, thus remaining functional and safe for several years.

Functional adaptations enhance the metal bus changer’s operational longevity.

Adapting to practical needs in order to avoid unnecessary wear shows a different facet of the metal bus shelters’ durability. For instance, several models of metal bus shelters feature tempered glass or metal side panels that can easily be interchanged if broken, as a means of avoiding replacement of the entire shelter. This approach reduces the total cost of maintenance adn elongates to lifetime of the shelter.

Some of the metal bus shelters come with drainage outlets in the canopy and the floor and are built to keeping stagnant water from accumulating in the shelters, metal structures and internal components (such as the seat and light fittings) from being damaged. Also, in metal shelters, the seatings are made of reinforced metal and also durable weather resistant plastics that can endure high intensity usage and cleaning cycles. These fittings and robust functional design features prove that the metal bus shelter can suite the functional and operational requirements of the everyday use from the commuters and withstand the pragmatic conditions.

Added Maintenance Routine and Quality After-Sales Support are Essential to the Lifespan of the Metal Bus Shelters

As much as a metal bus shelter is durable, its life span is highly dependent on the proper maintenance that is accompanied with dependable after support services such as from the transport authorities. Metal bus shelters The designated authorities should routinely check the bus shelters for the presence of rust, loose bolts, or any other for wear and tear, and also perform the necessary maintenance. For example, to stop major repairs, repairable loose bolts can be replaced, while uncoated areas can be retouched with paint. Most companies such as the Yeroo Group, will offer after support for their products covering maintenance guidance, spare parts, and even repair support.

This makes sure any problems with the shelter are solved as fast and effective as possible. A well maintained and supported panelled metal bus shelter with rest will last for 15-20 years or more with public transportation and service systems which makes it an investment that is both effective and trustworthy when cities are concerned.